Pasteurized Creams & Sponge

PASTEURIZED CREAMS

CONTINUOUS PROCESS

PREPARATION

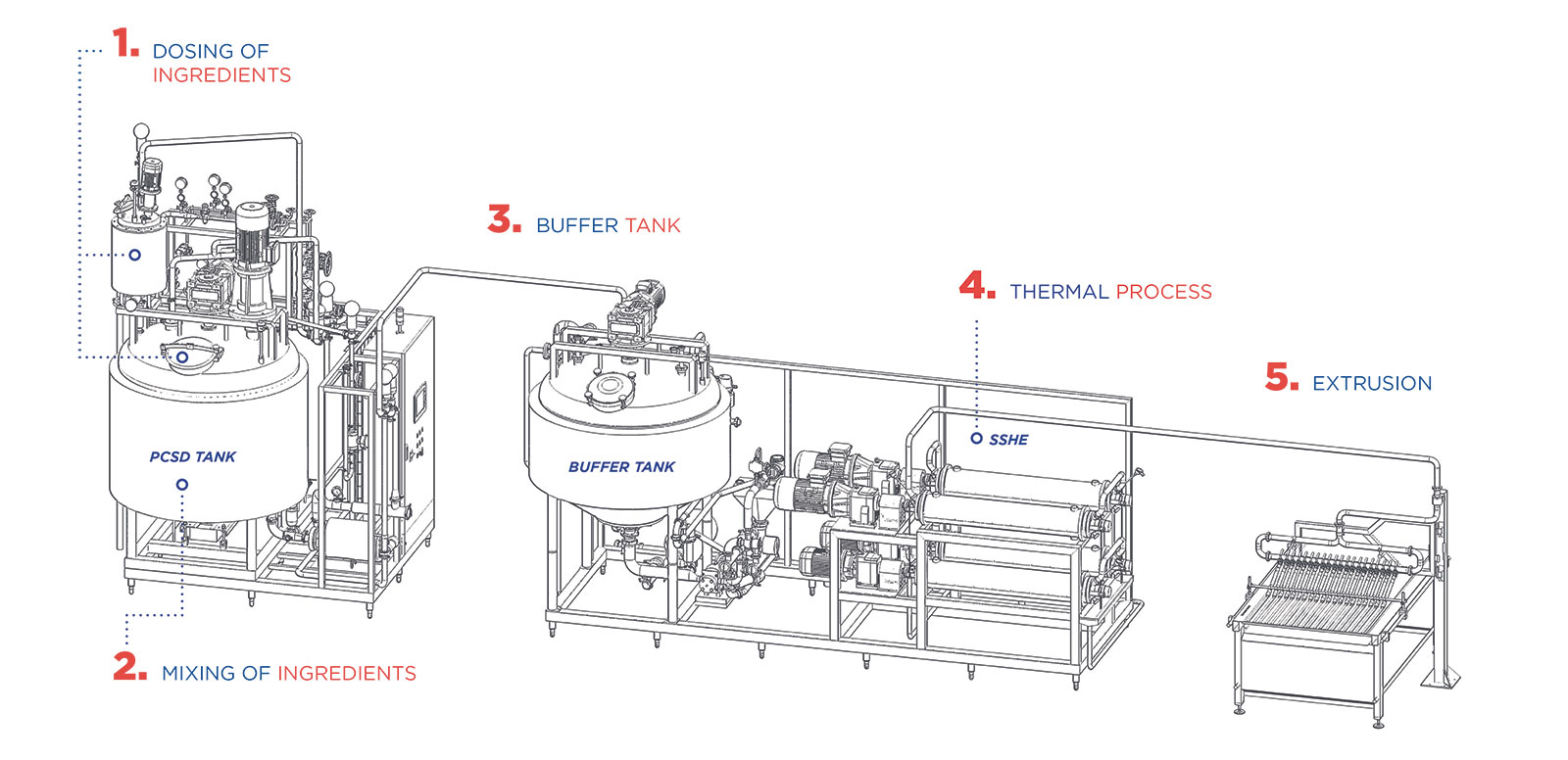

FULLY AUTOMATIC PROCESS – 5 STEPS

1. DOSING OF INGREDIENTS

Water dosed automatically through an electromagnetic flow meter

Oil dosed automatically through either a mass or a volumetric flow meter

Powder Ingredients dosed manually directly through the manhole or connected to an automatic powder dosing system

2. MIXING OF INGREDIENTS

In our PCSD tank, the bottom impeller (1450 rpm), the electroemulsifier (1450 rpm) and the anchor agitator (23 rpm) are activated to make sure all the ingredients are homogeneously spread into the mix. In this phase the product reaches a temperature of about 60°C.

PCSD TANK

• BOTTOM IMPELLER (1450 rpm)

• ELECTROEMULSIFIER (1450 rpm)

• ANCHOR AGITATOR (23 rpm)

3. BUFFER TANKS

Once the mixing process is over and the mix is ready, the product is pumped to a buffer tank, after which the process will swith from batch to continuous. The buffer tank holds the product at the given temperature while keeping it under a gentle agitation.

THERMAL PROCESS

SSHE

Scraped Surface Heat Exchangers

[A] CONTINUOUS PASTEURIZATION

The product is continuously pumped from the buffer tank to a series of 4 (or more if necessary) Scraped Surface Heat Exchangers (SSHE). The first SSHE, through the passage of steam in its double jacket, takes the product to pasteurization temperature (usually around 85°C). The product then goes through a holding pipe that guarantees the completion of the pasteurization process with the correct holding time.

[B] CONTINUOUS COOLING CRYSTALLIZATION AND AERATION

The remaining SSHEs are in charge of the cooling of the product. The cooling medias are usually tower water and glycol. This section of the process is of key importance to the crystallization of the product. Crystallization is the process through which the product goes from liquid to semi-solid (cream) and its succesful achievement is what gives the desired texture to each single cream. About half way through the cooling process, Nitrogen (or air) is injected into the product and then spread into all its volume by the mechanical force given by the scraping blades allowing the cream to achieve the set density value.

5. EXTRUSION

The product is now ready to be pumped to the extrusion system and layed down onto the sponge cake layer. Soren’s extruders are specifically designed to be connected to the C.I.P. return line during the washing cycles, thus allowing the operators to avoid the long and complicated dismounting process.

WHY CHOOSE WATER-BASED CREAMS

PRODUCT QUALITY

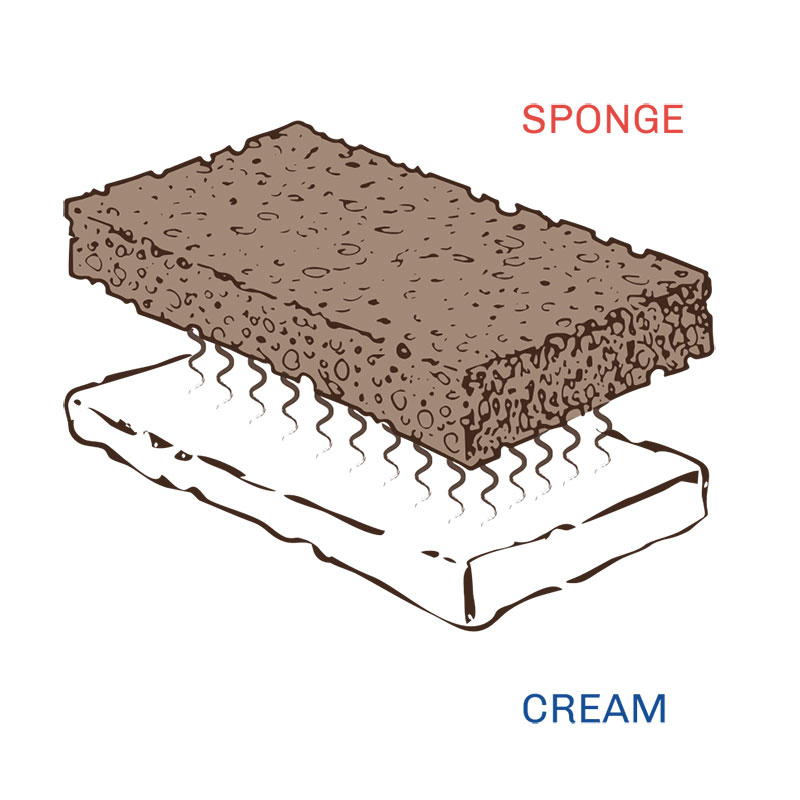

A standard cake consists of two elements: sponge cake and cream.

These two elements will interact with each other during the whole shelf life of the product by constantly transferring chemicals to one another. This phenomenon, called migration, takes place due to the natural tendency of a system to achieve overall balance including, of course, chemical.

The reason why this phenomenon is relevant to cakes is water activity (Aw), that represents the amount of water contained in a product that is “free to move” within the product and to interact with other elements.

In cakes filled with fat-based creams, water will naturally and gradually migrate from the sponge cake to the cream until Aw values are equal. As a result, after as little as two months of shelf life, the sponge cake will become dry and the product will no longer have its original sensorial qualities.

With Soren’s water-based cream technology it is now possible to avoid water migration by matching perfectly the water activities of sponge cake and cream, thus allowing the product to keep its original qualities all through its shelf life.

+ TASTE

Water-based creams contain a much higher quantity of water which, combined to the fact that they are oil in water emulsions (not water in oil, like fat-based creams) makes them much fresher and much lighter to the customer’s palate.

– COST

Being fat the most expensive ingredient in the recipe, a cream with a much lower amount of fat will reduce the cost of the single unit

+ HEALTH

Water based creams significantly reduce the calories and the amount of fat of the product

SPONGE

CONTINUOUS PROCESS

PREPARATION

FULLY AUTOMATIC PROCESS – 4 STEPS

OAM PROCESS TANK

Specifically designed to mix high viscosity products

1. DOSING OF INGREDIENTS

Water dosed automatically through an electromagnetic flow meter

Egg dosed automatically through a flow meter

Powder Ingredients dosed manually directly through the manhole or connected to an automatic powder dosing system

2. MIXING OF INGREDIENTS

Specifically designed to mix sponge batter, our OAM process tank is a high performing heavy duty machine. It has a rotor-stator fence agitation system with only a 2 mm space between its arms which allows to mix all ingredients with great efficiency.

3. BUFFER TANK

Once the mixing process is over and the mix is ready, the product is pumped to a buffer tank, after which the process will swith from batch to continuous. The buffer tank holds the product at the given temperature while keeping it under a gentle agitation.

4. TURBOAERATOR

The batter is continuously pumped through a TurboAerator which, through the injection and dispersion of Nitrogen (or air), allows the product to reach the desired density value.